Rockmass Monitoring

Silixa’s integrated DAS, DTS and DSS platform can monitor the rockmass response in real time or on demand, offering:

- Block cave monitoring

- Underground mine monitoring

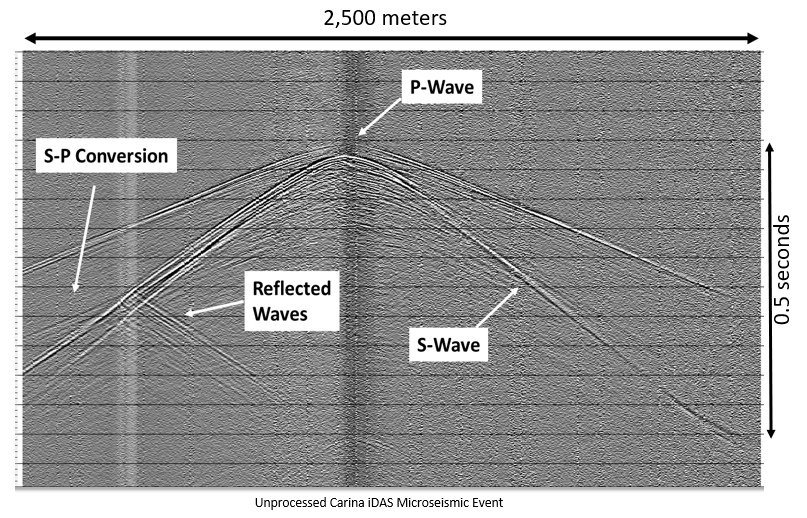

- Active and passive microseismic monitoring

- Active and passive tomographic imaging

- Precision strain monitoring solutions with DAS and DSS

- Shaft sinking temperature and strain monitoring

- Deformation and temperature monitoring for tunnels and drifts

- Surface slope stability and subsidence monitoring

- Water flow and seepage monitoring

- Vibration and blast monitoring

The distributed nature of the measurements means that a single fibre optic cable can be converted into a dense array sensor with thousands of measurement points. High density DAS, DTS and DSS data can be collected along tens of kilometres of optical fibre simultaneously.

The complete spatial and temporal coverage allows us to identify potential failure events before they occur, hence enabling operators to mitigate risks.

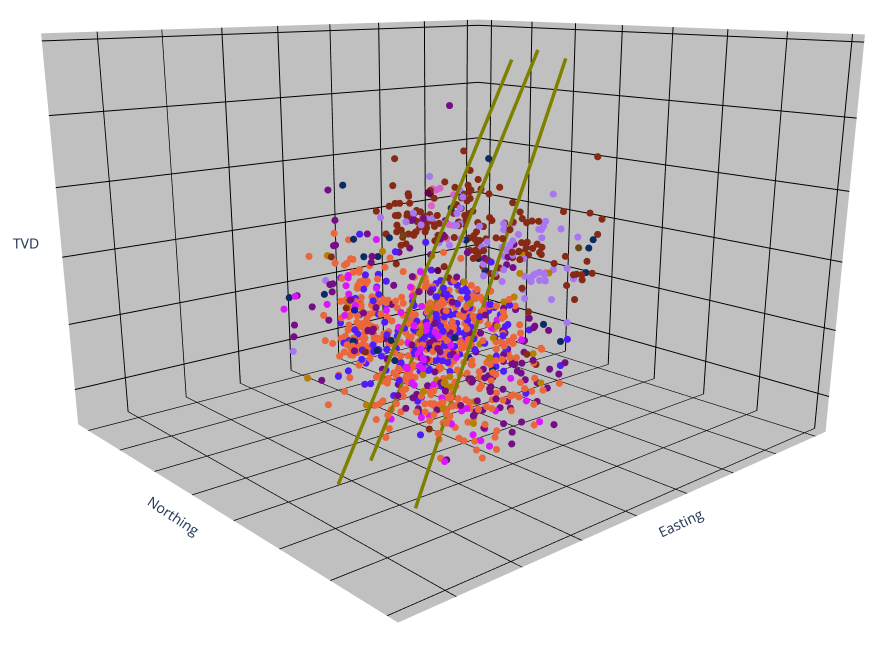

In underground mining operations, an integrated fibre sensing platform can be used to monitor microseismic activity, blasting, hydraulic conditioning, deformation monitoring, as well as provide imaging through active/passive tomography and vertical seismic profiles.

The comprehensive data provides a detailed image of the rockmass response to mining operation through

- plotting microseismic events location and propagation

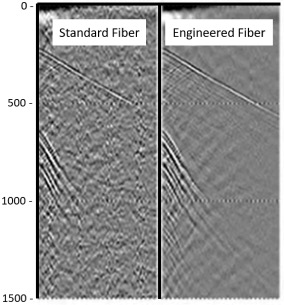

- mapping fracture growth, orientation and extent through standard fibre or Silixa’s highly sensitive engineered fibre, capable of detecting the smallest fractures within the rockmass

In addition, temperature analysis and dynamic and absolute strain measurements can provide further insight into the rockmass changes.

Distributed fiber optic sensing systems for rockmass monitoring can be modular. Borehole or surface-based cables can be added as operations expand, and multiple data types can be monitored continuously or on-demand through remote access. Fibre optic cables can be deployed temporarily or permanently to be used for multiple

In addition to high fidelity seismic acquisition via Carina® Sensing System, Silixa’s iDAS™ can also provide slow strain monitoring.

Slow strain (commonly 0.1Hz-1Hz) utilizes DAS’s unique flat system response and allows for measurements of 10μ‑ε. Silixa specific DSS interrogator can resolve absolute strain at a ±2 με. slow-strain monitoring has multiple uses for mining, including: