Seismic Surveys with DAS — Mineral Exploration

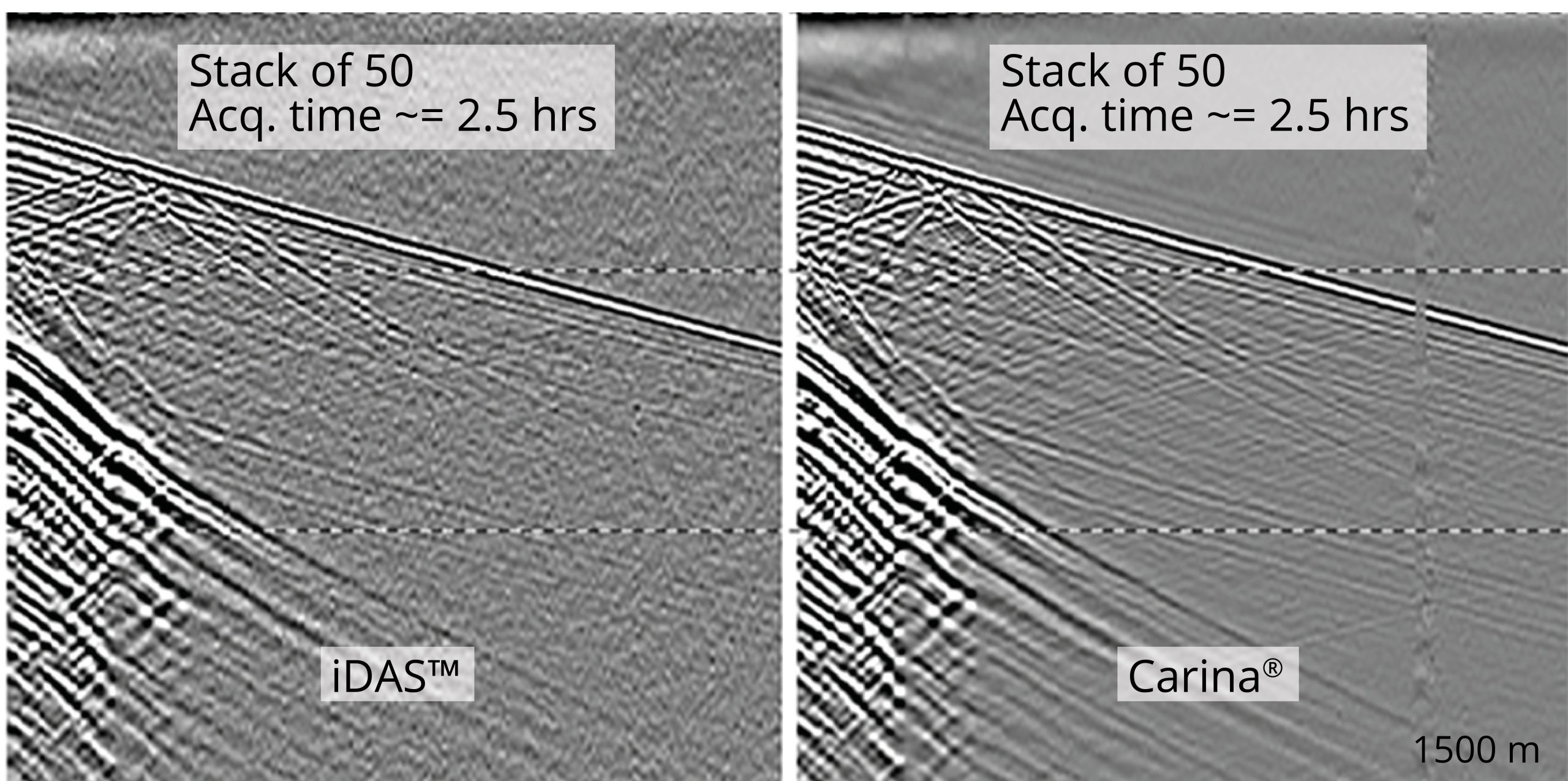

Silixa’s Distributed Acoustic Sensor (iDAS™) and Carina® Sensing System enable precise, reliable and cost-effective seismic imaging with ultra-high resolution to characterise and evaluate the subsurface.

Distributed acoustic sensing (DAS) is well suited technology for mineral exploration and mine planning due to the negligible cost of the fibre, its ease of deployment, and the speed of acquisition due to the sensitivity along the entire length of the fiber optic cable. The sensing element, the fiber optic cable, can be deployed either on the surface or downhole, permanently or temporarily.

DAS is highly effective for VSP surveys as its dense spatial sampling utilizes all the available borehole without the need of moving geophones multiple times to achieve coverage. The denser spatial sampling of DAS helps resolve complex geologic structures common to mining environments. The time saved moving geophones can be used to reduce costs, or further enhance subsurface resolution through additional trace collection and stacking.

Image courtesy of CO2CRC

- 3D/4D seismic surveys

- VSP — Vertical Sesimic Profiling

- Cross-hole tomography

- Ambient noise tomography

Given the high sensitivity of both the iDAS and the Carina Sensing System, seismic surveys can be carried out with minimal source effort, the Surface Orbital Vibrator (SOV). This ensures the repeatability and consistency of surveys with minimal environmental footprint in significantly less time and reduced costs.

Given the high sensitivity of both the iDAS and the Carina Sensing System, seismic surveys can be carried out with minimal source effort, the Surface Orbital Vibrator (SOV). This ensures the repeatability and consistency of surveys with minimal environmental footprint in significantly less time and reduced costs.

High-quality imaging capabilities

DAS has a broadband response with a noise floor similar to, or exceeding, geophones. Combined with dense spatial sampling the allows high-quality seismic imaging of the subsurface.

Flexible deployment

Fibre-optic cables can be temporarily or permanently deployed, remaining operational for years. They may be buried at the surface or installed in boreholes. The technology can be used in harsh and high-temperature environments and is suitable for surveys in both soft and hard rock.

Improved interpretation

With one cable DAS measurements can be combined with temperature (DTS) and strain (DSS) measurements to facilitate enhanced interpretation of geological structures, and hence improve exploration efficiency.